Introduction

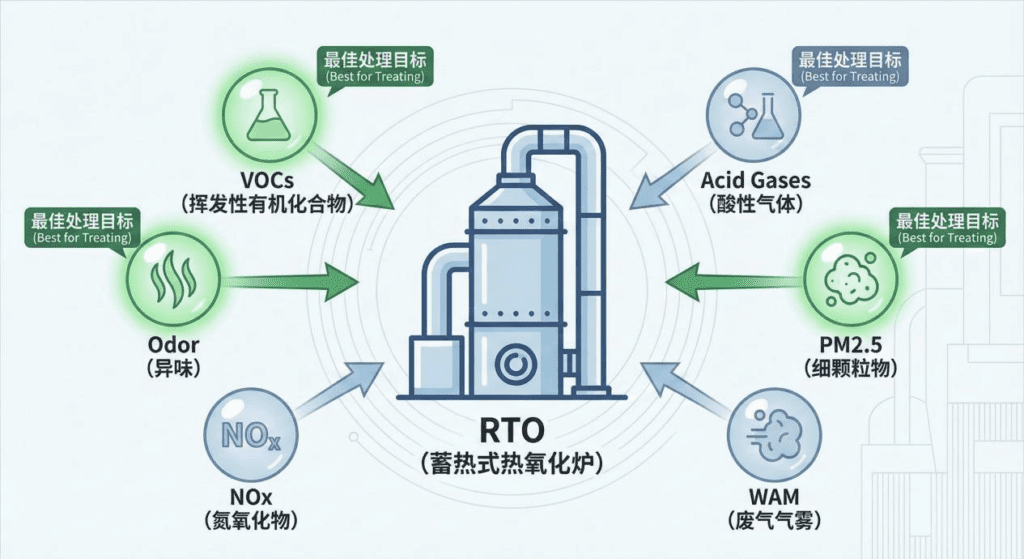

As global awareness of environmental challenges grows and regulatory bodies tighten air quality standards, industries around the world face increasing pressure to minimize their environmental impact. One of the most effective and widely adopted technologies for controlling industrial emissions, specifically volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), is the Regenerative Thermal Oxidizer (RTO). This advanced, energy‑efficient technology plays a vital role in ensuring that harmful pollutants are safely destroyed before they can be released into the atmosphere, promoting cleaner air and a healthier environment.

The increasing importance of compliance with international environmental regulations makes RTOs not just a technology of choice but a strategic necessity for industries looking to stay ahead in today’s regulatory landscape.

This article delves into what RTOs are, how they function, the regulatory frameworks driving their adoption worldwide, and the numerous benefits they provide to industries aiming for sustainable growth.

What is a Regenerative Thermal Oxidizer (RTO)?

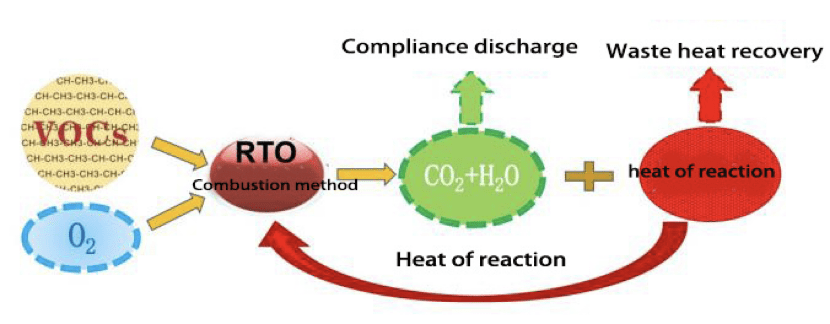

A Regenerative Thermal Oxidizer (RTO) is a highly effective pollution control system designed to destroy VOCs and other hazardous air pollutants (HAPs) generated by various industrial processes. It works by passing exhaust air through a series of ceramic heat‑exchange beds, where heat is stored and then reused for thermal oxidation. This process not only destroys harmful pollutants but does so in an energy‑efficient manner by minimizing the need for external fuel sources.

Unlike traditional oxidizers, which continuously burn fuel to maintain high temperatures, RTOs capture the heat from the exhaust air, making them one of the most energy-efficient solutions available for industrial air pollution control. This regenerative process allows RTOs to achieve destruction efficiencies exceeding 95%, ensuring that VOCs and HAPs are reduced to their harmless byproducts—primarily carbon dioxide and water.

How RTOs Work: The Science Behind the Technology

Understanding how RTOs work requires a look at the core of their regenerative design:

Inlet of Contaminated Air: VOC‑laden air is drawn from industrial processes, such as coating, printing, or chemical manufacturing.

Heat Recovery: The air passes through ceramic media beds, where the heat from previously treated air is absorbed, reducing the need for additional fuel.

Thermal Oxidation: At temperatures ranging from 760°C to 820°C (1400°F to 1500°F), the VOCs undergo oxidation, breaking down into non‑hazardous substances like carbon dioxide (CO₂) and water vapor (H₂O).

Heat Regeneration: The treated air exits through the ceramic beds, transferring its heat back into the system, which helps preheat incoming contaminated air.

Continuous Cycling: RTOs use automated valves and multiple heat‑exchange beds to ensure constant operation and efficiency, even as one bed regenerates while the others treat the air.

By using heat recovery, RTOs ensure a high level of operational efficiency, significantly lowering energy consumption and environmental impact compared to conventional thermal oxidizers.

Why RTOs Matter: The Environmental and Regulatory Imperatives

1. Global Emissions Targets and Air Quality Standards

Air pollution, including emissions of VOCs and HAPs, is one of the leading contributors to global environmental degradation. These pollutants can cause respiratory diseases, environmental harm, and contribute to the formation of ground‑level ozone, which exacerbates climate change.

In response, governments around the world have established strict regulations aimed at controlling industrial emissions. Some of the key frameworks include:

United States: Clean Air Act (CAA) – The U.S. Environmental Protection Agency (EPA) enforces air quality standards through the CAA, requiring industries to reduce VOC and HAP emissions. RTOs are often a preferred solution for achieving compliance.

European Union: Industrial Emissions Directive (IED) 2010/75/EU – The IED sets out strict guidelines for industrial air emissions, encouraging industries to adopt Best Available Techniques (BAT), which includes technologies like RTOs.

China: Air Pollution Prevention and Control Action Plan – China has aggressively tackled air pollution with regulations that mandate VOC control in industrial facilities. RTOs help companies meet these stringent emissions standards.

Japan: Air Pollution Control Law – Japan also enforces stringent air pollution controls, especially in industries with high VOC emissions, where RTOs are a commonly used solution.

These regulatory frameworks make it clear that RTOs are not just a technical solution—they are a necessity for compliance and play an essential role in protecting public health and the environment.

RTOs and Regulatory Compliance: A Closer Look

United States

In the U.S., the Clean Air Act and its provisions, such as the National Emission Standards for Hazardous Air Pollutants (NESHAP), have set high standards for controlling industrial emissions. Many industries—particularly those involved in chemical manufacturing, printing, and painting—are required to use advanced air pollution control technologies. RTOs offer several advantages in meeting these stringent standards:

High destruction efficiency for VOCs and HAPs

Reliability and proven performance

Minimal environmental impact

Failure to comply can result in hefty fines, penalties, and even shutdowns. By investing in RTO technology, industries can avoid costly non‑compliance issues and maintain smooth operations.

European Union

The Industrial Emissions Directive (IED) is another key driver of RTO adoption in Europe. The IED mandates that industries adopt Best Available Techniques (BAT) to minimize emissions, and RTOs are frequently cited as a recommended BAT for VOC control. This regulation pushes industries in sectors such as automotive, printing, and chemical manufacturing to use energy-efficient solutions like RTOs to meet EU-wide environmental standards.

China

With rapid industrialization, China faces significant air quality challenges. The government has set aggressive air pollution control targets, and as a result, many industries are turning to RTOs to comply with local regulations and national air quality goals. RTOs have become a cornerstone of the country’s effort to reduce VOC emissions and improve public health.

Other Global Markets

Emerging economies such as India, Brazil, and Mexico are also tightening their environmental regulations. These countries are following the lead of their developed counterparts by adopting similar air quality standards, which is driving demand for efficient emission control technologies like RTOs.

Key Industries Benefiting from RTOs

RTO technology is applicable across a wide range of industries that generate VOCs or HAPs in their production processes, including:

Automotive Coating and Painting

Pharmaceutical Manufacturing

Chemical Processing

Food and Beverage Flavoring

Printing and Packaging

Adhesives and Sealants

Petrochemical Plants

For these industries, RTOs represent a reliable and cost-effective way to reduce harmful emissions while maintaining regulatory compliance and improving operational efficiency.

The Benefits of RTOs: Beyond Compliance

1. High Efficiency in VOC Destruction

RTOs are capable of destroying up to 99% of VOCs and HAPs, making them ideal for industries with strict emission standards.

2. Significant Energy Savings

By recovering heat from the exhaust air, RTOs significantly reduce fuel consumption, leading to substantial energy savings and lower operational costs.

3. Scalable and Flexible Design

RTO systems can be tailored to accommodate different volumes and compositions of exhaust air, making them versatile enough for both large and small industrial operations.

4. Improved Odor Control

Industries such as food processing and printing, which face concerns over offensive odors, benefit from the odor-neutralizing capabilities of RTOs, improving both workplace and community air quality.

5. Reduced Carbon Footprint

RTOs contribute to sustainability by reducing energy usage and minimizing greenhouse gas emissions, aligning with global sustainability goals and corporate social responsibility (CSR) initiatives.

Best Practices for RTO Design and Implementation

While RTO technology offers significant advantages, successful implementation requires careful consideration:

1. Comprehensive Emission Profiling

A detailed analysis of exhaust gas composition, temperature, and flow rates is crucial for selecting the right RTO model and ensuring optimal performance.

2. Proper Material Selection

Choosing the appropriate materials for the heat media and components is essential for handling aggressive pollutants and ensuring the system’s longevity.

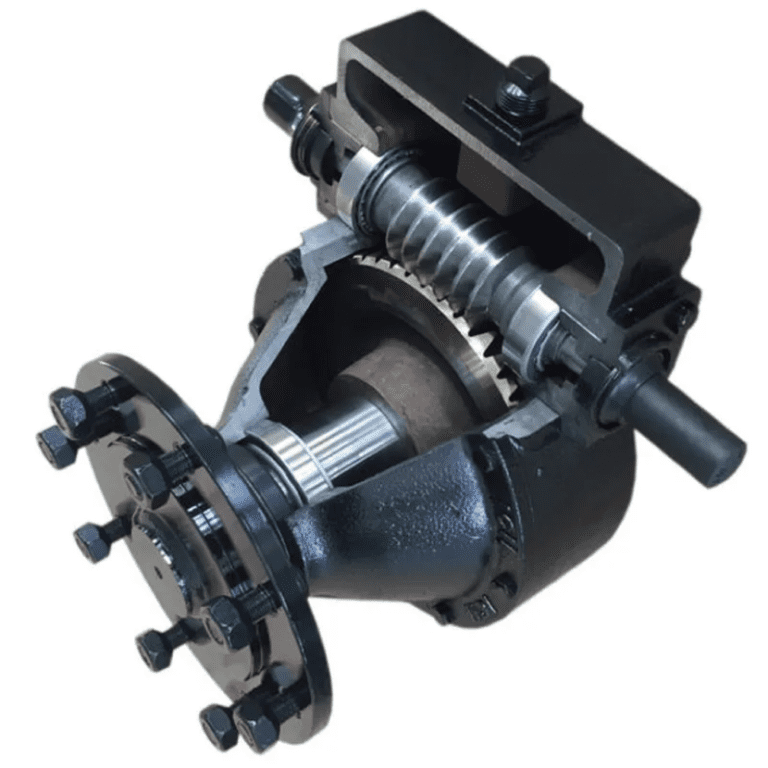

3. System Integration

RTOs must be integrated into existing plant infrastructures with careful attention to ductwork, fans, and control systems to ensure seamless operation.

4. Ongoing Maintenance

Regular maintenance of the RTO system is critical to keep it running efficiently and ensure long-term compliance. Inspections of valves, burners, and other key components should be part of a routine service schedule.

Future Trends in RTO Technology

1. Advanced Digitalization

AI-driven analytics and remote monitoring systems are transforming RTO operation by improving predictive maintenance and real‑time performance tracking.

2. Next-Generation Materials

Innovations in ceramic materials are improving the heat recovery process and extending the operational life of RTO systems.

3. Hybrid Systems

Some facilities are exploring hybrid approaches that combine RTOs with catalytic or adsorption systems for enhanced performance, particularly in managing low-concentration VOCs.

4. Green Energy Integration

There is a growing trend to integrate RTOs with renewable energy systems, further reducing the environmental impact of industrial operations.