In the domain of industrial air pollution control, the Regenerative Thermal Oxidizer (RTO) represents a sophisticated technology engineered to eliminate volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and odorous emissions through high-temperature oxidation. This process converts harmful substances into innocuous byproducts such as carbon dioxide and water vapor, achieving destruction efficiencies typically exceeding 99%. The regenerative component, utilizing ceramic heat recovery media, facilitates exceptional thermal efficiency, often surpassing 95%, thereby optimizing energy utilization and reducing operational expenditures. However, the efficacy and longevity of an RTO system are contingent upon rigorous maintenance protocols. Neglecting maintenance can lead to diminished performance, increased downtime, and non-compliance with environmental regulations, such as those stipulated by the U.S. Environmental Protection Agency (EPA) or equivalent international bodies.

This article delineates comprehensive maintenance strategies for RTO systems, encompassing preventive, predictive, and corrective approaches. By integrating structured maintenance schedules, diagnostic tools, and best practices, industrial operators can ensure sustained operational reliability and cost-effectiveness. To enhance clarity, tabular formats are employed to outline maintenance timelines, common issues, and resolution strategies. The insights provided herein are particularly pertinent for systems detailed on resources like Regenerative Thermal Oxidizer explanatory pages, which offer foundational knowledge on RTO functionality.

Understanding Key Components of RTO Systems

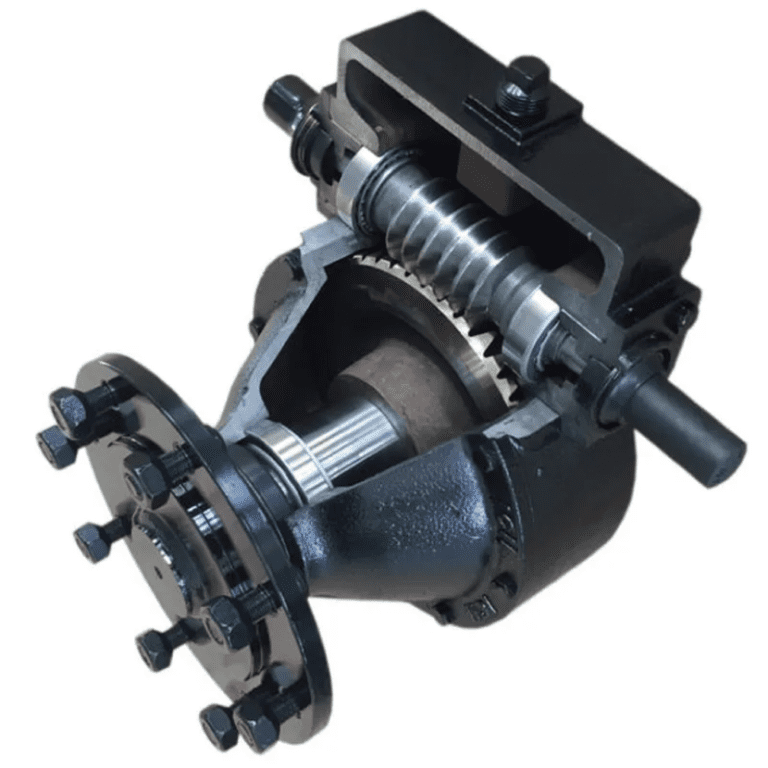

Prior to exploring maintenance protocols, it is imperative to comprehend the principal components of an RTO. These systems comprise multiple chambers housing ceramic media beds, which alternate between heat absorption from exhaust gases and preheating inlet streams. Additional elements include rotary or poppet valves for gas flow direction, combustion chambers equipped with burners, blowers for airflow management, and control systems for operational oversight. The ceramic media, often structured in honeycomb configurations, is pivotal for heat recovery, while valves ensure seamless switching between inlet, outlet, and purge cycles to prevent contaminant bypass.

Maintenance efforts must prioritize these components, as degradation—such as media fouling, valve wear, or burner inefficiency—can compromise system integrity. For instance, in high-VOC environments, particulate accumulation on media beds can elevate pressure drops, necessitating targeted cleaning regimens.

Types of Maintenance for RTO Systems

Maintenance for RTOs can be categorized into three primary types: preventive, predictive, and corrective. Each serves a distinct purpose in preserving system functionality.

- Preventive Maintenance: Scheduled interventions to avert failures, including routine inspections and component replacements based on manufacturer guidelines.

- Predictive Maintenance: Utilizes monitoring technologies to forecast potential issues, such as vibration analysis or thermal imaging, enabling proactive resolutions.

- Corrective Maintenance: Addresses failures post-occurrence, focusing on rapid restoration to minimize production interruptions.

The following table elucidates these maintenance types, their objectives, and implementation frequencies, providing a structured overview for operational planning.

| Maintenance Type | Objectives | Typical Frequency | Key Activities |

| Preventive | Prevent breakdowns, extend component life | Daily/Weekly/Monthly/Annually | Inspections, lubrication, filter replacements |

| Predictive | Anticipate failures through data analysis | Continuous monitoring with periodic reviews | Vibration monitoring, thermography, emissions testing |

| Corrective | Restore functionality after faults | As needed | Component repairs, system recalibration |

This classification facilitates a balanced maintenance strategy, optimizing resource allocation while mitigating risks.

Recommended Maintenance Schedule

A meticulously crafted maintenance schedule is foundational to RTO longevity. Schedules should be tailored to operational parameters, such as exhaust volume, VOC concentration, and environmental conditions. Below is a comprehensive table outlining a standard maintenance timetable for key RTO components, assuming moderate-duty operation (e.g., 8,000-10,000 hours annually).

| Component | Daily Tasks | Weekly Tasks | Monthly Tasks | Annual Tasks |

| Ceramic Media Beds | Monitor pressure drops | Visual inspection for fouling | Clean if pressure exceeds thresholds | Full replacement or deep cleaning |

| Valves (Rotary/Poppet) | Check for leaks | Lubricate moving parts | Inspect seals and actuators | Overhaul or replace worn components |

| Burners and Combustion Chamber | Verify flame stability | Clean nozzles | Test ignition systems | Inspect refractory linings |

| Blowers and Fans | Listen for unusual noises | Check belt tension | Align and balance | Bearing replacement |

| Control Systems | Review alarm logs | Update software | Calibrate sensors | Comprehensive system audit |

| Exhaust Stack and Ductwork | Monitor emissions | Inspect for corrosion | Clean accumulations | Structural integrity check |

Adherence to this schedule can extend RTO lifespan beyond 15-20 years, with adjustments based on site-specific data from continuous emissions monitoring systems (CEMS).

Ceramic Media Maintenance

The ceramic media, central to heat recovery, requires vigilant upkeep to prevent efficiency losses. Fouling from particulates or condensates can increase energy consumption by 10-20%. Preventive measures include installing upstream filters and scheduling bake-out cycles to volatilize deposits. Predictive tools, such as differential pressure sensors, signal when cleaning is warranted. For corrective actions, media extraction and high-pressure washing or chemical treatments restore performance, though care must be taken to avoid structural damage.

Valve and Sealing System Maintenance

Valves ensure precise gas flow management, and their failure can result in cross-contamination or safety hazards. Rotary valves, prevalent in modern designs, benefit from external placement for accessible servicing. Routine lubrication with high-temperature greases and seal inspections mitigate wear. Advanced systems incorporate fluorosilicone seals for enhanced durability, reducing replacement frequency.

Burner and Combustion Maintenance

Burners maintain oxidation temperatures (typically 760-980°C), and inefficiencies can elevate fuel costs. Daily flame checks and weekly nozzle cleanings prevent carbon buildup. Annual refractory inspections safeguard against thermal stresses, ensuring combustion chamber integrity.

Common Issues and Troubleshooting

RTO systems may encounter operational challenges, necessitating prompt diagnostics. The ensuing table catalogs prevalent issues, symptoms, potential causes, and remedial strategies, serving as a reference for maintenance personnel.

| Issue | Symptoms | Possible Causes | Troubleshooting Steps |

| High Pressure Drop | Increased blower load, reduced flow | Media fouling, duct blockages | Inspect and clean media; check filters |

| Valve Malfunction | Leakage, uneven heating | Worn seals, actuator failure | Replace seals; test actuators |

| Burner Instability | Flameouts, high emissions | Fuel impurities, ignition faults | Clean fuel lines; recalibrate controls |

| Excessive Energy Use | Elevated fuel bills | Insulation degradation, inefficiencies | Audit heat recovery; repair insulation |

| Emissions Non-Compliance | Failed stack tests | Incomplete oxidation, sensor errors | Verify temperatures; calibrate CEMS |

Implementing root cause analysis, such as failure mode and effects analysis (FMEA), enhances troubleshooting efficacy.

Best Practices for RTO Maintenance

To optimize maintenance outcomes, adhere to these practices:

- Training Programs: Equip personnel with specialized knowledge on RTO operations and safety protocols.

- Documentation: Maintain detailed logs of inspections, repairs, and performance metrics for trend analysis.

- Spare Parts Inventory: Stock critical components like seals and sensors to expedite repairs.

- Environmental Considerations: Factor in ambient conditions, such as humidity or corrosives, when planning maintenance.

- Integration of Technology: Leverage AI-driven monitoring for real-time diagnostics and predictive alerts.

These practices not only prolong equipment life but also align with sustainability goals by minimizing emissions and energy waste.

Advanced Maintenance Technologies

Contemporary RTO systems incorporate cutting-edge technologies to streamline maintenance. For example, cloud-based platforms enable remote monitoring via mobile applications, allowing for parameter optimization and early fault detection. AI software analyzes operational data to predict maintenance needs, reducing unplanned downtime by up to 30%. Additionally, vacuum insulation techniques enhance energy savings, while modular designs facilitate component access and upgrades.

Conclusion

The maintenance of Regenerative Thermal Oxidizer systems is paramount to ensuring their reliability, efficiency, and compliance in industrial emissions control. By adopting structured schedules, leveraging diagnostic tools, and embracing advanced technologies, operators can mitigate risks and optimize performance across diverse applications. As environmental regulations intensify, proactive maintenance strategies will be instrumental in achieving sustainable operations. For expert guidance and high-performance RTO solutions, consider SSJ UK Limited, a leading manufacturer specializing in VOC treatment and energy-saving technologies. With over 68 patents, including 21 invention patents, and core expertise in thermal energy, combustion, sealing, and automation, SSJ UK Limited delivers rotary valve RTO systems boasting >99.5% decomposition efficiency and >97% heat recovery. Their innovative features, such as AI-integrated monitoring, mobile app oversight, and customizable zeolite molecular sieve rotors, ensure seamless integration and low-maintenance operations. Collaborating with prestigious institutions like Xi’an Jiaotong University, SSJ UK Limited provides tailored systems that comply with stringent standards while minimizing energy costs, making them an exemplary partner for global industrial needs. Explore their offerings for comprehensive insights into Regenerative Thermal Oxidizer fundamentals and advanced implementations.