Introduction to Flexographic Printing and Emission Control

Flexographic printing, often referred to as flexo printing, stands as a cornerstone in the modern packaging and labeling industry. This versatile printing method employs flexible relief plates to transfer ink onto a wide array of substrates, including paper, plastic films, and metallic foils. Its efficiency in high-volume production makes it indispensable for creating everything from food wrappers to corrugated boxes. However, the process generates volatile organic compounds (VOCs) through the evaporation of solvents in inks and cleaning agents, posing significant environmental and health risks if not properly managed.

In response to stringent environmental regulations and the push for sustainable manufacturing, regenerative thermal oxidizers (RTOs) have emerged as a highly effective solution for controlling these emissions in flexographic printing operations. For more details on our advanced RTO systems tailored for printing applications, visit our website at https://regenerativethermaloxidiser.com/.

The Environmental Imperative in Flexographic Printing

The flexographic printing sector faces mounting pressure from global regulations such as the U.S. EPA’s Clean Air Act and Europe’s Industrial Emissions Directive, which mandate the reduction of VOC emissions to prevent air pollution and smog formation. Untreated emissions can contribute to ground-level ozone, a key component of urban smog, and expose workers to hazardous air pollutants. By implementing RTO technology, printing facilities can achieve destruction efficiencies exceeding 99%, transforming harmful VOCs into harmless water vapor and carbon dioxide. This not only ensures regulatory compliance but also aligns with corporate sustainability goals, reducing the carbon footprint of printing operations.

Understanding Regenerative Thermal Oxidizers

Regenerative thermal oxidizers represent an advanced form of thermal oxidation technology designed for energy efficiency and high-performance emission control. Unlike traditional incinerators, RTOs utilize a regenerative heat exchange process to recover and reuse thermal energy, making them particularly suitable for industries like flexographic printing where exhaust streams contain low to moderate concentrations of VOCs.

Core Components of an RTO System

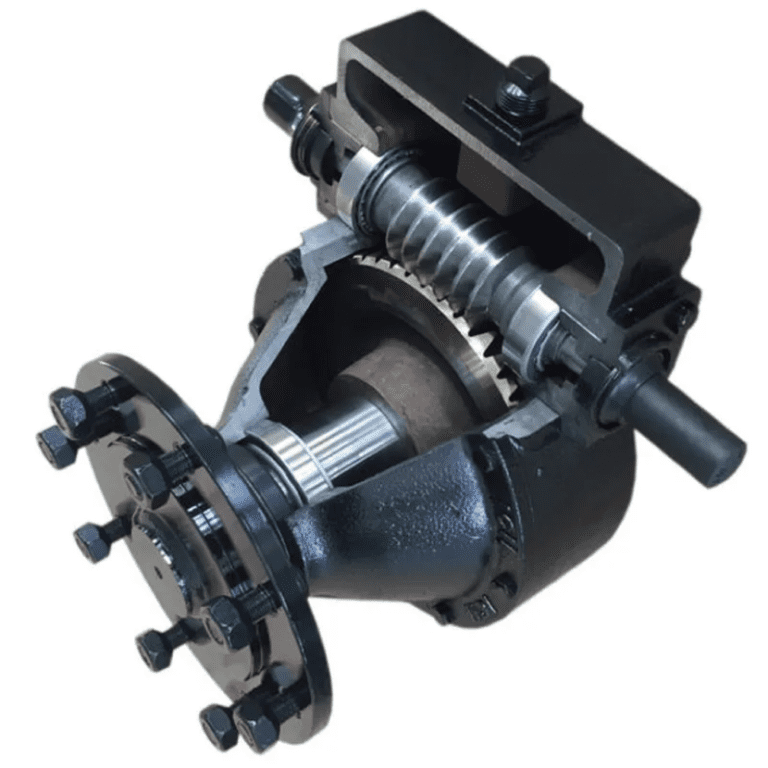

At the heart of an RTO are ceramic media beds that act as heat exchangers. These beds, typically made from high-alumina ceramics, store heat from the combustion process and transfer it to incoming exhaust gases, preheating them to oxidation temperatures without excessive fuel consumption. Additional components include a combustion chamber where VOCs are oxidized at temperatures around 1,500°F (815°C), burner systems for supplemental heat, and sophisticated control valves that direct gas flow between multiple beds—usually two or three—to maintain continuous operation.

In flexographic printing setups, the RTO is often integrated downstream from dryers and presses, capturing solvent-laden air directly from the exhaust stacks. This modular design allows for scalability, accommodating small-scale label printers to large-scale packaging converters.

How RTOs Operate in Flexographic Printing Environments

The operation of an RTO begins with the collection of VOC-rich exhaust from the printing presses. As the gas enters the system, it passes through a preheated ceramic bed, raising its temperature close to the auto-ignition point of the contaminants. In the combustion chamber, any remaining heat is supplied to ensure complete oxidation, breaking down complex hydrocarbons into simpler, non-toxic compounds.

A key feature is the regenerative cycle: after oxidation, the hot clean gas exits through another ceramic bed, transferring its heat for the next incoming stream. This cycle switches periodically via poppet valves, achieving thermal efficiencies up to 95-97%. For flexo printing, where exhaust volumes can fluctuate with production speeds, variable frequency drives and advanced PLC controls optimize performance, minimizing energy use during low-load periods.

Benefits of Implementing RTOs in Flexographic Printing

Adopting regenerative thermal oxidizers in flexographic printing yields multifaceted benefits, extending beyond mere emission control to enhance overall business resilience.

Environmental and Regulatory Advantages

RTOs excel in destroying a broad spectrum of VOCs common in flexo inks, such as toluene, xylene, and ethyl acetate, with minimal secondary emissions like NOx or CO. This high destruction rate helps printing facilities meet or exceed air quality standards, avoiding hefty fines and shutdowns. Moreover, by reducing greenhouse gas contributions, RTO-equipped operations can qualify for environmental certifications like ISO 14001, appealing to eco-conscious clients in the consumer goods sector.

Economic and Operational Efficiencies

The energy recovery aspect of RTOs translates to substantial cost savings. In a typical flexographic printing plant, fuel costs for emission control can drop by 50-70% compared to direct thermal oxidizers, thanks to the regenerative process. Maintenance is streamlined with self-cleaning features that handle particulate matter from inks, extending equipment lifespan and reducing downtime. Over time, these efficiencies can offset initial installation costs, with payback periods often under three years for high-volume operations.

Additionally, RTOs support process optimization by allowing the use of low-VOC inks without compromising print quality, fostering innovation in sustainable printing practices.

Health and Safety Enhancements

By effectively capturing and destroying hazardous air pollutants, RTOs improve indoor air quality in printing facilities, safeguarding worker health against respiratory issues and long-term exposure risks. This proactive approach not only complies with OSHA standards but also boosts employee morale and productivity, creating a safer workplace environment.

Real-World Applications and Case Studies

In practical scenarios, RTOs have proven transformative for flexographic printing companies. For instance, a mid-sized packaging converter in the Midwest U.S. integrated a custom RTO from CMN Industry Inc., reducing VOC emissions by 98% while cutting annual energy costs by $150,000. The system handled variable exhaust flows from multiple presses, demonstrating adaptability to dynamic production schedules.

Another example involves a European label manufacturer facing stringent EU directives. By retrofitting an existing flexo line with an RTO, they achieved zero non-compliance incidents and enhanced their market position as a green supplier to major food brands. These cases underscore the technology’s reliability across diverse operational scales and regulatory landscapes.

Future Trends in RTO Technology for Flexographic Printing

Looking ahead, advancements in RTO design are poised to further integrate with Industry 4.0 principles. Smart sensors and AI-driven analytics will enable predictive maintenance and real-time emission monitoring, optimizing performance amid evolving ink formulations and substrate materials. Hybrid systems combining RTOs with catalytic elements could lower operating temperatures, reducing energy demands even more.

As the flexographic printing industry shifts toward water-based and UV-curable inks, RTOs will adapt to handle emerging contaminants, ensuring long-term sustainability.

Embracing Sustainable Innovation

Regenerative thermal oxidizers are not merely compliance tools but strategic assets for flexographic printing operations seeking environmental stewardship and operational excellence. By investing in this technology, companies like yours can navigate regulatory challenges while driving efficiency and innovation. At CMN Industry Inc., we specialize in bespoke RTO solutions designed for the unique demands of printing environments.