Understanding Center Pivot Irrigation Systems

Center pivot irrigation represents a cornerstone of modern agricultural practices, particularly in regions where water efficiency is paramount. This method involves a rotating sprinkler system that pivots around a central point, delivering water uniformly across circular fields. At the heart of this technology lies the center pivot irrigation gearbox, a robust mechanical component designed to drive the system’s movement with precision and reliability. These gearboxes convert rotational power from motors into the controlled torque necessary for the pivot’s wheels, ensuring steady progression without compromising structural integrity.

The adoption of center pivot systems has revolutionized farming by optimizing water usage, reducing labor costs, and enhancing crop uniformity. In arid climates or large-scale operations, such as those in the American Midwest or Australian outback, these gearboxes enable farmers to irrigate hundreds of acres efficiently. By minimizing evaporation and runoff, they align with global sustainability goals, conserving precious water resources while supporting higher yields in crops like corn, wheat, and soybeans.

Historical Evolution and Technological Advancements

The concept of center pivot irrigation dates back to the 1940s, pioneered by inventors seeking solutions to uneven watering in traditional flood methods. Early gearboxes were simple, often prone to breakdowns under constant load. Over decades, advancements in materials science and engineering have transformed them into high-performance units. Modern gearboxes incorporate alloy steels and precision machining, offering enhanced durability against corrosion and wear.

Innovations such as variable frequency drives (VFDs) integrated with gearboxes allow for adjustable speeds, adapting to varying soil conditions or crop needs. This evolution reflects a broader shift toward smart agriculture, where data from soil sensors informs gearbox operations, promoting energy efficiency and reducing operational downtime.

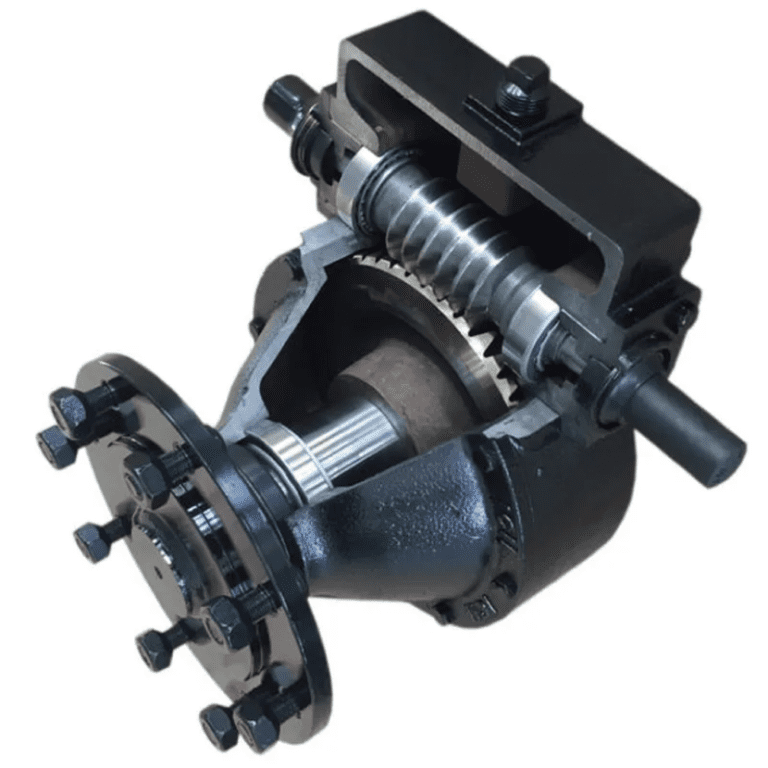

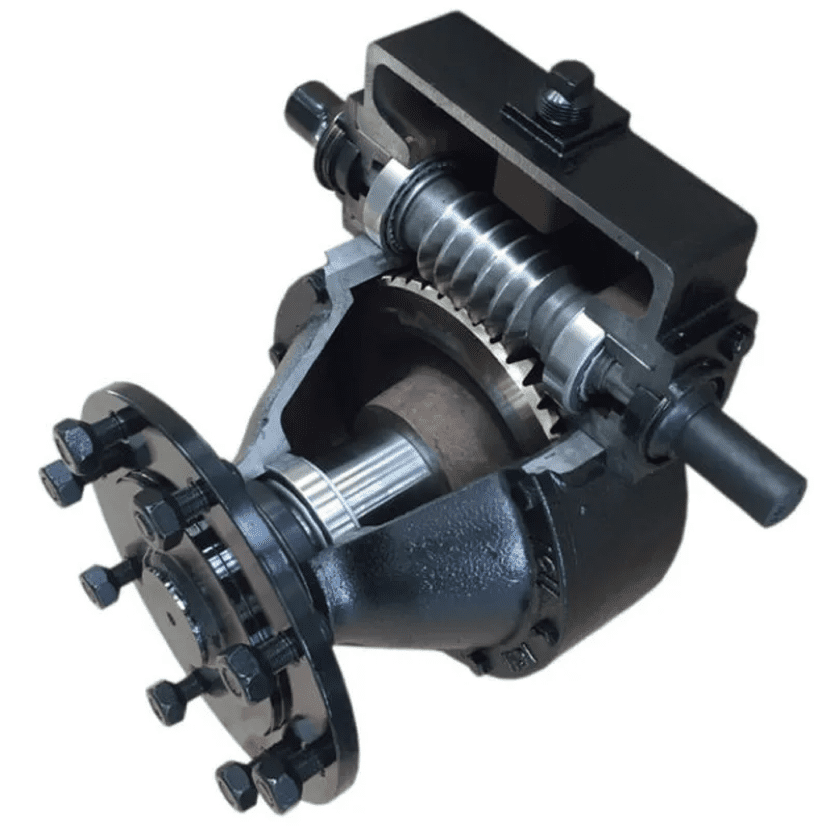

Key Features of a Center Pivot Irrigation Gearbox

A well-engineered center pivot irrigation gearbox is characterized by several critical features that ensure optimal performance. Primarily, it boasts a high gear reduction ratio, typically ranging from 30:1 to 50:1, which amplifies torque while slowing rotational speed to match the pivot’s leisurely pace—often covering a full circle in 24 to 48 hours. This design prevents overload on the drive motors and maintains consistent water application.

Sealing mechanisms are another vital aspect, with advanced oil seals and gaskets protecting internal components from dust, water ingress, and agricultural chemicals. Many models include overload clutches or shear pins as safety features, disengaging the drive in case of obstructions like rocks or uneven terrain, thereby safeguarding the entire system from damage.

Materials and Construction for Durability

The construction of these gearboxes emphasizes longevity in demanding environments. Housings are commonly made from ductile iron or aluminum alloys, providing a balance of strength and weight reduction. Gears themselves are hardened steel, often with helical or worm configurations for smoother operation and reduced noise levels.

In coastal or high-salinity areas, corrosion-resistant coatings such as epoxy or galvanization extend service life. These material choices not only enhance mechanical reliability but also contribute to lower maintenance frequencies, allowing farmers to focus on crop management rather than equipment repairs.

Operational Mechanics in Irrigation Applications

In operation, the center pivot irrigation gearbox functions as the intermediary between the power source and the drive wheels. Power is transmitted via universal joints or drive shafts, with the gearbox modulating output to achieve uniform speed across the pivot’s span, which can extend up to half a mile. This ensures that end guns or corner systems receive adequate drive without straining the central mechanism.

For variable-rate irrigation, gearboxes with multiple speed settings enable zone-specific watering, adjusting for topography or soil variability. This precision minimizes water waste and nutrient leaching, fostering healthier root systems and more resilient crops against drought or pests.

Integration with Automation and Control Systems

Contemporary gearboxes are increasingly integrated with automated controls, including GPS-guided navigation and remote monitoring via IoT devices. Farmers can adjust gearbox parameters from smartphones, responding to weather forecasts or soil moisture readings in real-time. Such integration not only boosts efficiency but also supports predictive maintenance, where vibration sensors detect early signs of wear, preventing costly failures during critical growing seasons.

Benefits for Agricultural Productivity and Sustainability

The implementation of a reliable center pivot irrigation gearbox yields multifaceted benefits. Economically, it reduces energy consumption by up to 25% compared to older models, lowering fuel or electricity costs for large operations. Environmentally, precise water delivery curtails overuse, preserving aquifers and reducing the ecological footprint of farming.

From a productivity standpoint, uniform irrigation promotes even crop maturation, facilitating easier harvesting and higher market quality. In diverse applications, from forage crops to high-value orchards, these gearboxes enable year-round cultivation in controlled environments, bolstering food security amid climate variability.

Economic and Environmental Case Studies

Real-world examples underscore these advantages. In California’s Central Valley, farms utilizing advanced gearboxes have reported yield increases of 15-20% in almond production, attributed to consistent moisture levels. Similarly, in water-stressed regions like sub-Saharan Africa, subsidized gearbox upgrades have empowered smallholders to double output while halving water usage, demonstrating the technology’s role in sustainable development.

Maintenance Strategies for Long-Term Performance

To maximize the lifespan of a center pivot irrigation gearbox, proactive maintenance is essential. Routine inspections should include checking oil levels and quality, as contaminated lubricants can accelerate gear wear. Annual alignments ensure proper shaft positioning, while torque checks verify that bolts remain secure against vibrational loosening.

In off-seasons, thorough cleaning removes residue buildup, and storage in sheltered areas prevents exposure to elements. For gearboxes in extreme conditions, such as freezing winters, anti-freeze additives in oils maintain fluidity.

Troubleshooting Common Issues

Common challenges include gear slippage or overheating, often stemming from inadequate lubrication or misalignment. Solutions involve using synthetic oils for better thermal stability and installing temperature gauges for early detection. In cases of seal failure, upgrading to double-lip seals can enhance protection, ensuring the gearbox operates flawlessly through multiple seasons.

Selecting the Ideal Gearbox for Your System

Choosing the right center pivot irrigation gearbox requires evaluating several factors. Capacity must align with the pivot’s length and load—longer spans demand higher torque ratings. Compatibility with existing motors, whether electric or hydraulic, is crucial for seamless integration.

Budget considerations should weigh initial costs against long-term savings from efficient models. Consulting manufacturers’ specifications and seeking expert advice can guide selections tailored to specific farm layouts, soil types, and crop rotations.

Customization Options and Upgrades

Many suppliers offer customizable gearboxes, such as those with reinforced housings for hilly terrains or low-profile designs for compact installations. Upgrades like electric brakes or regenerative drives further enhance functionality, allowing for retrofits that modernize older systems without full replacements.

Future Innovations in Center Pivot Gearbox Technology

Looking ahead, the trajectory of center pivot irrigation gearboxes points toward greater intelligence and sustainability. Emerging trends include the incorporation of AI for adaptive speed control, optimizing water distribution based on predictive analytics. Lightweight composites may replace traditional metals, reducing energy demands and easing installation.

As renewable energy sources like solar power gain traction, gearboxes compatible with variable inputs will become standard, supporting off-grid operations. These advancements promise to make irrigation more resilient to climate challenges, ensuring agriculture’s adaptability in an uncertain future.

Global Implications for Food Production

On a broader scale, innovative gearboxes will play a key role in addressing global food demands. By enabling efficient irrigation in marginal lands, they contribute to reducing hunger and promoting equitable resource distribution, aligning with international sustainability agendas.